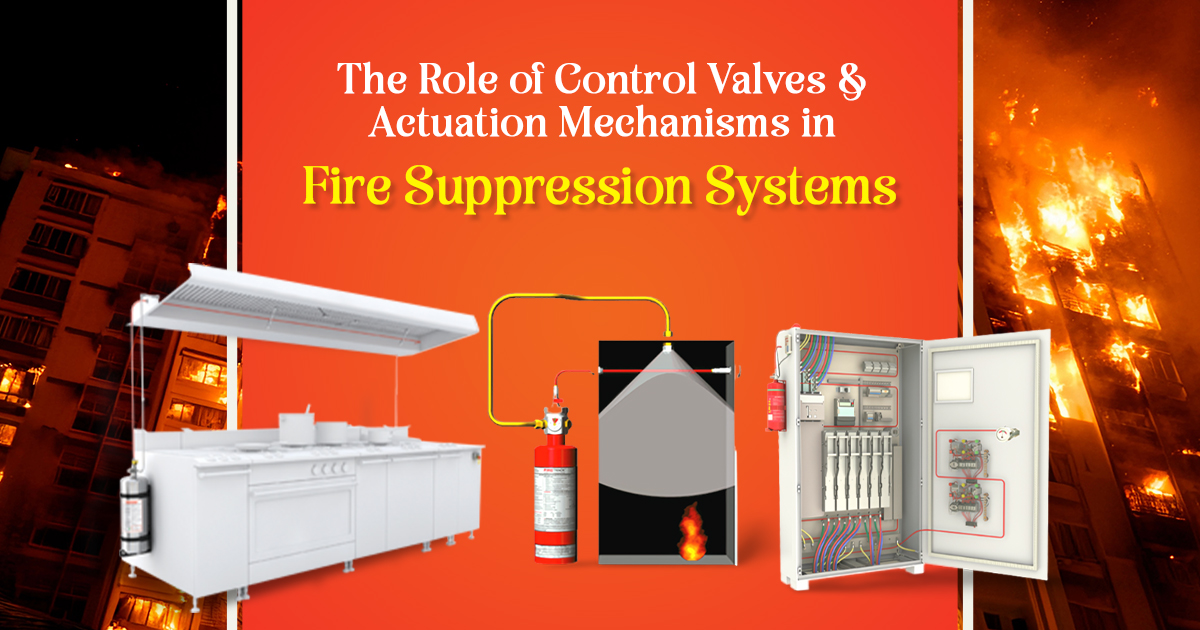

The Role of Control Valves and Actuation Mechanisms in Fire Suppression Systems

- May 27, 2025

What happens if a fire starts and no one is there to see it?

That’s a real concern in places like data centers, factories, and commercial kitchens. Fires spread fast and give little time to react. When there’s no one on-site to respond, the system needs to take action on its own.

That’s where the fire suppression system takes over. But the true workhorses inside that system? The control valves and actuation mechanisms. The system depends on them to function when it’s most needed.

Understanding Fire Suppression Systems

A fire suppression system is designed to detect a fire early and stop it before it gets out of control. These systems go beyond traditional extinguishers and are used in areas where fires must be handled automatically.

How the fire suppression system works:

When smoke, fire, or heat is detected in the surroundings, sensors instantly transmit a signal that opens control valves and switches on the system. So that the firefighting agent can be released immediately and the fire can be extinguished.

This quick reaction saves equipment, individuals, and property, even if no one is around.

Understanding Control Valves

Control valves are the parts that control where the firefighting agent goes. They stay closed until the system tells them to open, then they open right away to release the agent.

Control valve types:

● Deluge valves – utilized where a wide and rapid spread is required

● Pre-action valves – are appropriate perfectly in water-sensitive applications

● Pressure reducing valves – offer safe and consistent flow

Actuation Mechanisms Explained

The actuation mechanism activates the control valves. They respond as quickly as a fire is detected.

They can be:

1. Mechanical – activated by heat

2. Electric – triggered by smoke or heat sensors

3. Pneumatic – powered by compressed air

Each type has its place, but they all must act fast and without failure.

Reliability and Safety Considerations

If a valve fails or an actuator delays, the entire system is at risk. That puts fire safety on the line. That’s why installation, inspection, and real-world testing must be done by trained professionals using certified fire fighting equipment.

Maintenance and Testing Requirements

Keep your system ready with consistent checks.

| Frequency | What to Do |

| Monthy | Check for leaks, blockages, or corrosion |

| Quartely | Test the actuator function |

| Annually | Run a full functional test of the system |

Document everything and act fast on any issues.

Innovations and Smart Technologies

Modern systems now include:

➔ Remote monitoring and diagnostics

➔ Instant alerts on performance or faults

➔ Integration with building safety systems

This gives teams better visibility and faster decision-making.

Control valves and actuators play a central role in every fire suppression system. Their quick and accurate response is what allows the system to detect trouble and take action before a fire spreads.

Is your facility ready for an emergency?

Let Kanex Fire help you build a system that works when you need it most.

Explore our complete line of trusted fire fighting equipment today!